PFA COATING SERVICES

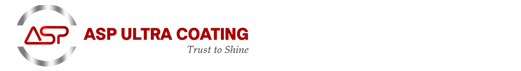

PFA (Perfluoroalkoxy) coating is a multi-step process that first requires careful preparation of the surface, and application of primer followed by masking. After these three steps, the substrate is either dipped into a PFA solution or the PFA coating is evenly sprayed on. After the coating is applied, curing is done in a regulated oven. Curing initiates cross-linking for durability. This is followed by quality checks to rectify any flaws. The use of a final finishing technique will depend on the application. This painstaking process (PFA coating) offers protection, chemical resistance and an enhanced lifespan to different industrial surfaces.

Key features of PFA Coating by ASP Ultra Coating

| Description | Colour | Max used temperature in °C/°F | Cure temperature in °C/°F | Film Build per Coat in mil | Max Total Film Build in mil |

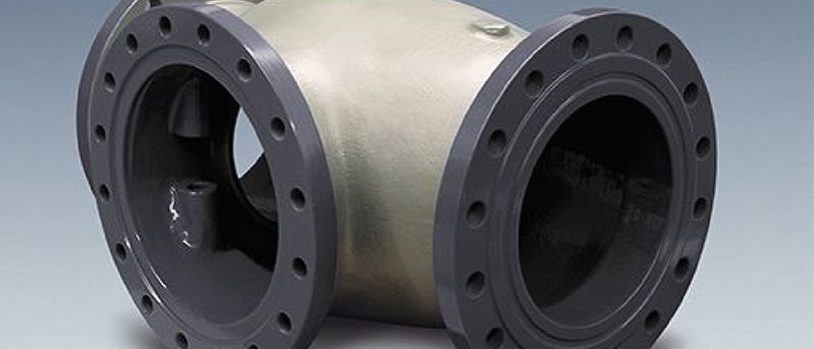

| Abrasion Resistant | Light Grey | 260/500 | 391/735 | 0.8 – 2.0 | 10.0 |

| Permeation Resistant | Ruby Red | 260/500 | 391/735 | 4.0 – 7.0 | 20.0 |

| Standard Grade | Clear | 260/500 | 391/735 | 1.0 – 4.0 | 10.0 |

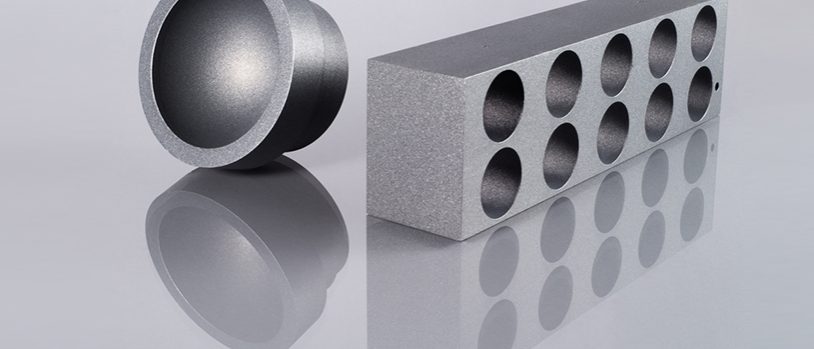

PFA coating shows high chemical resistance. It is insensitive to strong mineral acids, inorganic bases, inorganic oxidising agents, and saline solutions that contain some organic molecules such as alcohols, aldehydes, ethers, aromatics, anhydrides, aliphatic hydrocarbons, fluorocarbons, chlorocarbons and others.

The continuous service temperature of PFA coatings applied to carbon or stainless steel is between -60°C and 400°C.

PFA coatings have good non-stick qualities. Even at high temperatures, they have a high level of impact and electrical resistance. It offers increased versatility as it is available in powder and water-based forms. Our PFA coating systems protect wide metallic substrates, including steel, stainless steel, aluminium, and many more.

Properties of PFA coating

- High Processing Temperature Stability

- High Melting Strength

- Superior Crack Resistance

- Superior Stress Resistance

- Minimal Friction Coefficient

We are committed to providing accuracy and quality in each coating project Our PFA Coating procedure entails the application of a strong, homogeneous PFA layer that ensures ideal adhesion and coverage on different substrates. Regardless of the harsh chemicals or extreme temperatures, our PFA Coating Services offer a reliable way to extend the lifespan and improve the functionality of your components.

Modern technology and an expert team come together at ASP Ultra Coating to guarantee excellent coatings surpassing industry standards.

Visit ASP Ultra Coating for PFA Coating Services that enhance the parts’ chemical resistance and thermal stability. Discuss your specific coating needs with us right now, and let our expertise and latest processes provide a solution that meets the standards of your industry.