PTFE COATING SERVICES

PTFE is used for both PTFE homopolymers and polymers created by tetrafluoroethylene copolymerization with additional monomers. Fluoroethylene polymers contain various halogens and polymers with varying compositions. Polymers may have variable chain lengths (molecular weights).

Mechanical keying occurs between the PTFE coating and the substrate’s surface. It bonds the two materials.

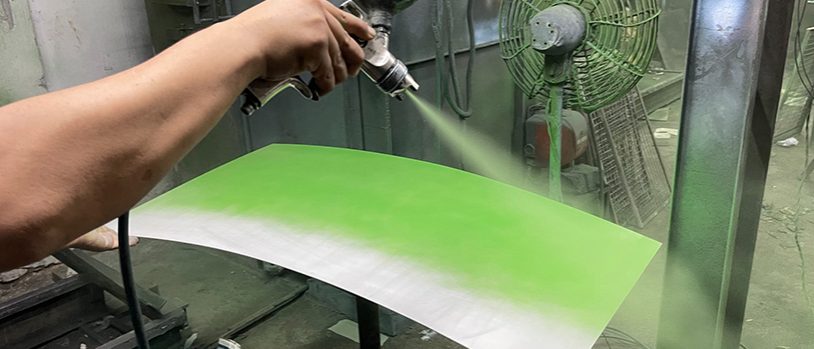

PTFE coating is done using two processes – the conventional, air-atomized spraying method and the relatively new, electrostatic method.

Air atomized spraying uses a syphon, gravity, or pressure feed to deliver the coating to the spray gun. When the gun’s trigger is pressed, the coating runs through the nozzle in a fluid stream. As the fluid exits the nozzle, compressed air from the centre of the nozzle forms a hollow cone around it, shattering the coating into small droplets and transferring velocity to it. Additional jets of compressed air from the nozzle further break up the droplets, forming an elliptical pattern.

In electrostatic coating, the fluid is atomized and negatively charged. The electrically neutral surface is relatively positive in comparison to the coating droplets which are negatively charged. The charge differential attracts the coating particles to the surface, where they remain until they are cured.

Key Features of PTFE Coating by ASP Ultra Coating

| Description | Colour | Max used temperature in °C/°F | Cure temperature in °C/°F | Film Build per Coat in mil | Max Total Film-built in mil |

| Standard Film Build | Green | 260/500 | 325/725 | 0.5 – 1.5 | 3.0 |

| High Film Build | Grey | 260/500 | 399/750 | 0.8 – 3.0 | 8.0 |

Properties of PTFE Coating

PTFE coating shows remarkable qualities, such as:

- Can work at extremely high temperatures

- Non-stick quality

- Minimal surface friction

- Extremely strong resistance to solvents and chemicals

- Extremely high electrical resistance

- Resistance to corrosion, UV radiation, and weather

- Non-toxic, biocompatible and inert

PTFE Coating Services at ASP Ultra Coating takes advantage of these properties to offer a reliable and long-lasting solution for protective coatings.

To achieve the best adhesion and coverage on substrates, we apply a robust and uniform PTFE layer during the PTFE coating process. We offer customised services for your unique needs.

Choose ASP Ultra Coating for PTFE Coating Services that enhance the non-stick properties and durability of your crucial components. Contact us today to discuss your specific coating needs and experience the difference our expertise and advanced processes can make for your industry.